Deputy laboratory manager Simone Post conducting a fire test at OMPG. (Image rights: OMPG/Steffen Beikirch)

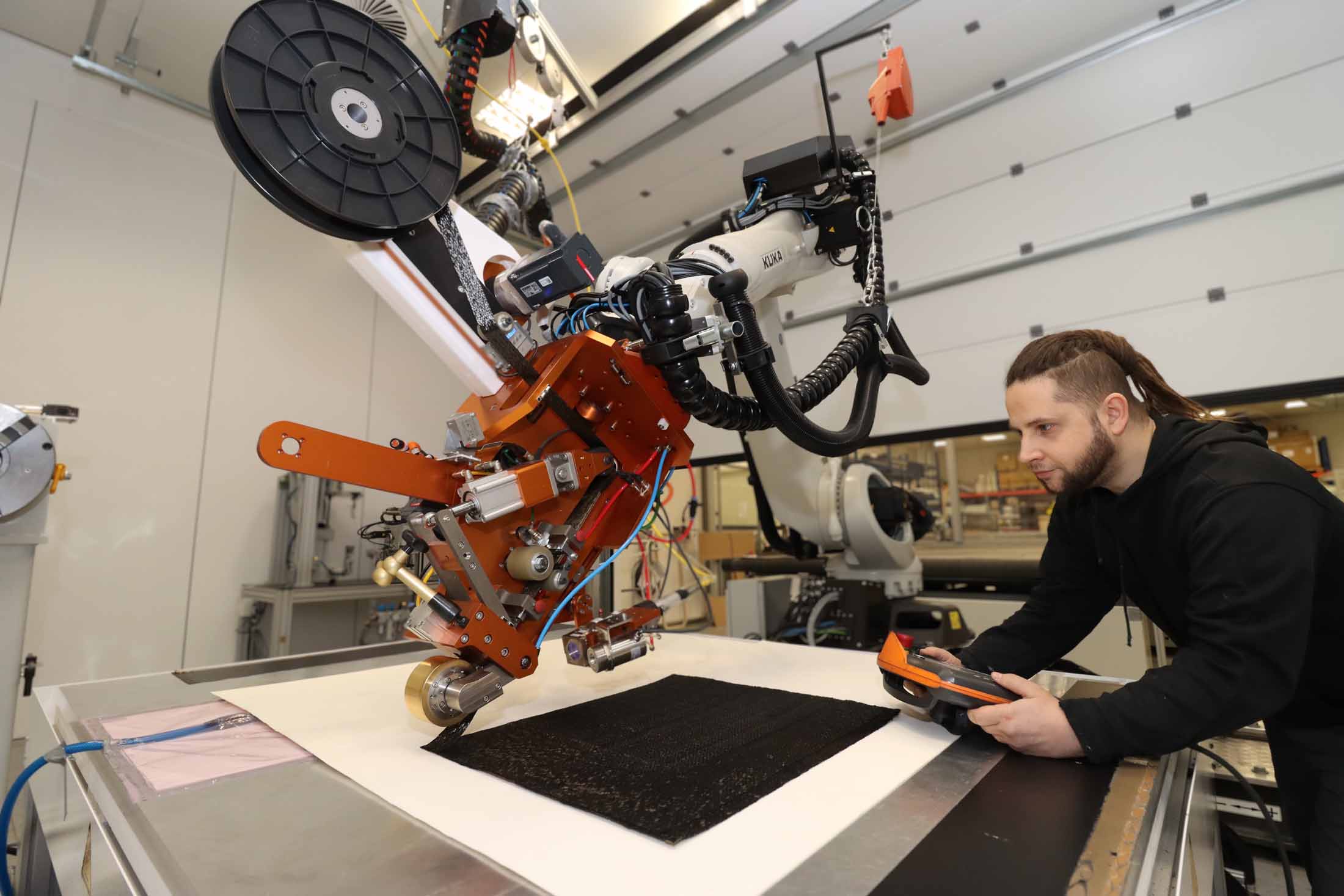

Unidirectionally reinforced tapes are key materials for efficient and sustainable lightweight construction. They enable components to be manufactured in a targeted, resource-saving, and performance-optimized manner by placing fibers exactly where they are needed for mechanical stress. This provides tailor-made semi-finished products for lightweight construction. At the K trade fair, TITK will be presenting the results of a research project on this topic. Specifically: new, dry narrow-band fabrics based on 50K carbon fiber rovings.

Other exhibits from the TITK Group document the industry's growing interest in the multi-award-winning Caremelt® bio-hot melt adhesive. It has recently been adopted for production by, for example, the industry leader in animal burials, ROSENGARTEN from Bad Bergen, and Kneisz Design from Weimar. Caremelt® has also been on display at Expo 2025 in Osaka (Japan) since April and will remain there until mid-October. As the first completely bio-based and biodegradable hot melt adhesive, it does not require any fossil resources and offers the possibility of making products that are already manufactured sustainably completely environmentally friendly.

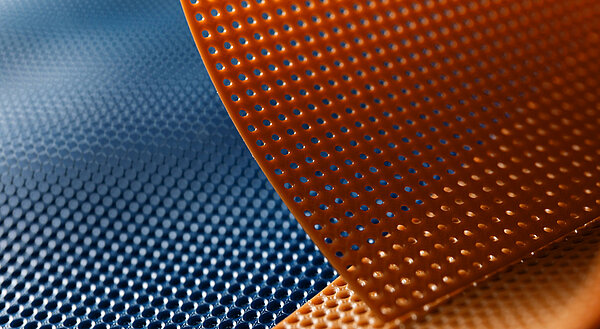

Polymer-based radiation elements for dielectric resonator antennas are aimed at a completely different area of application. These highly specific components are used in antennas for local broadband systems in industry, forestry, and agriculture, for security services, and for Wi-Fi hotspots in building radio systems and in means of transport. TITK has been researching these polymer semi-finished products for some time and has succeeded in making them more attractive than conventional products with high permittivity and low attenuation loss.

TITK has collaborated with the Günther Köhler Institute for Joining Technology and Materials Testing (Jena) and the Society for Manufacturing Technology and Development (Schmalkalden) to investigate how the processing procedures for metal 3D printing can be made sustainable and recyclable. The project “Circularity-optimized process chain for the additive manufacturing of metallic tool components via material extrusion” has now been completed since June, allowing concrete results to be presented in Düsseldorf.

Last but not least, OMPG will of course be presenting many suitable testing services for plastics at the TITK Group's booth, including mechanical tests, emission tests, exposure tests, and flammability tests.

TITK Group at K from October 8 to 15 in Düsseldorf – Hall 7, Level 0, Booth B24.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/b/csm_brandpruefungen-und-elektroanwendungen_7036bf8d6b.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/8/a/csm_biologische-pruefungen_b330c70d45.jpg)